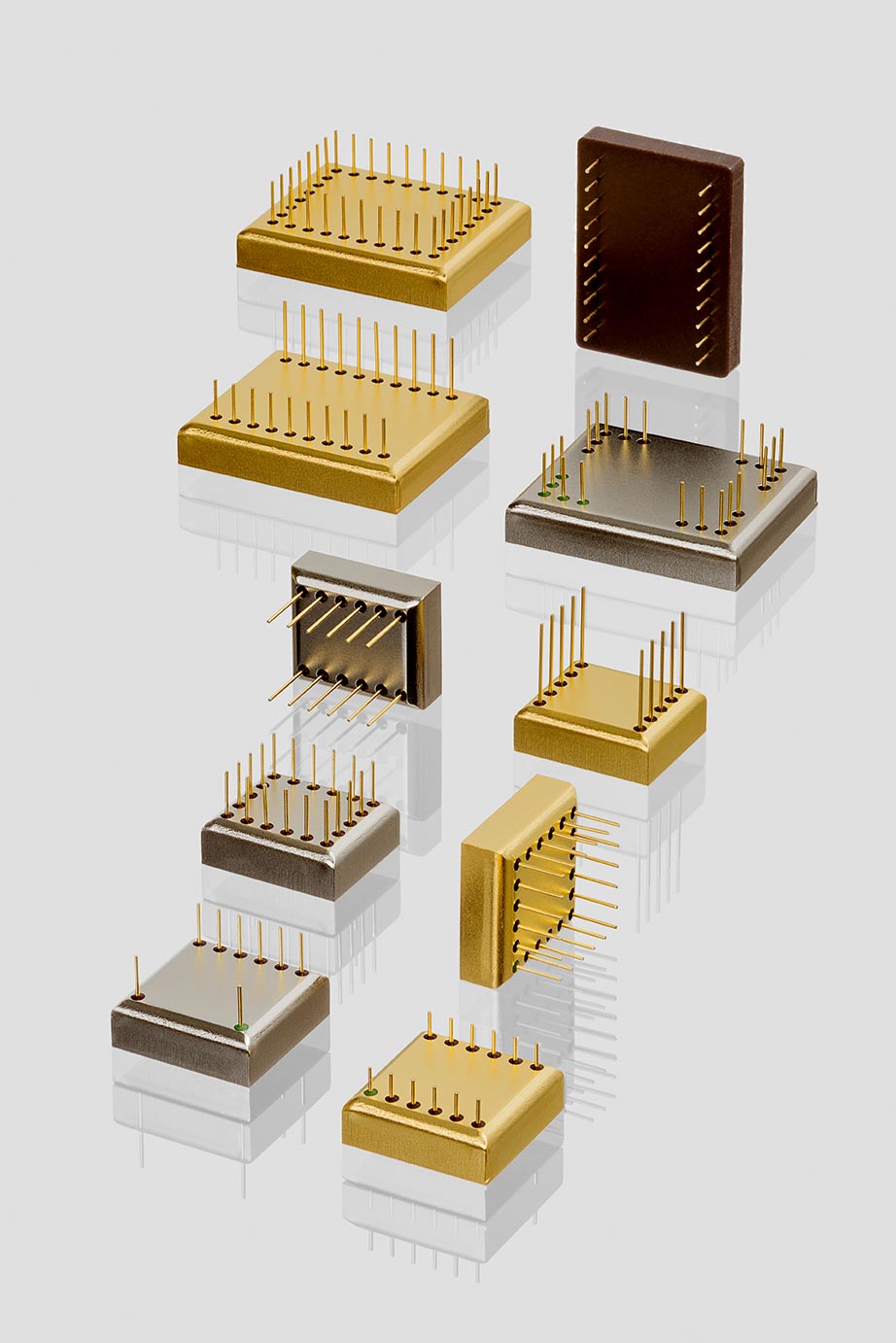

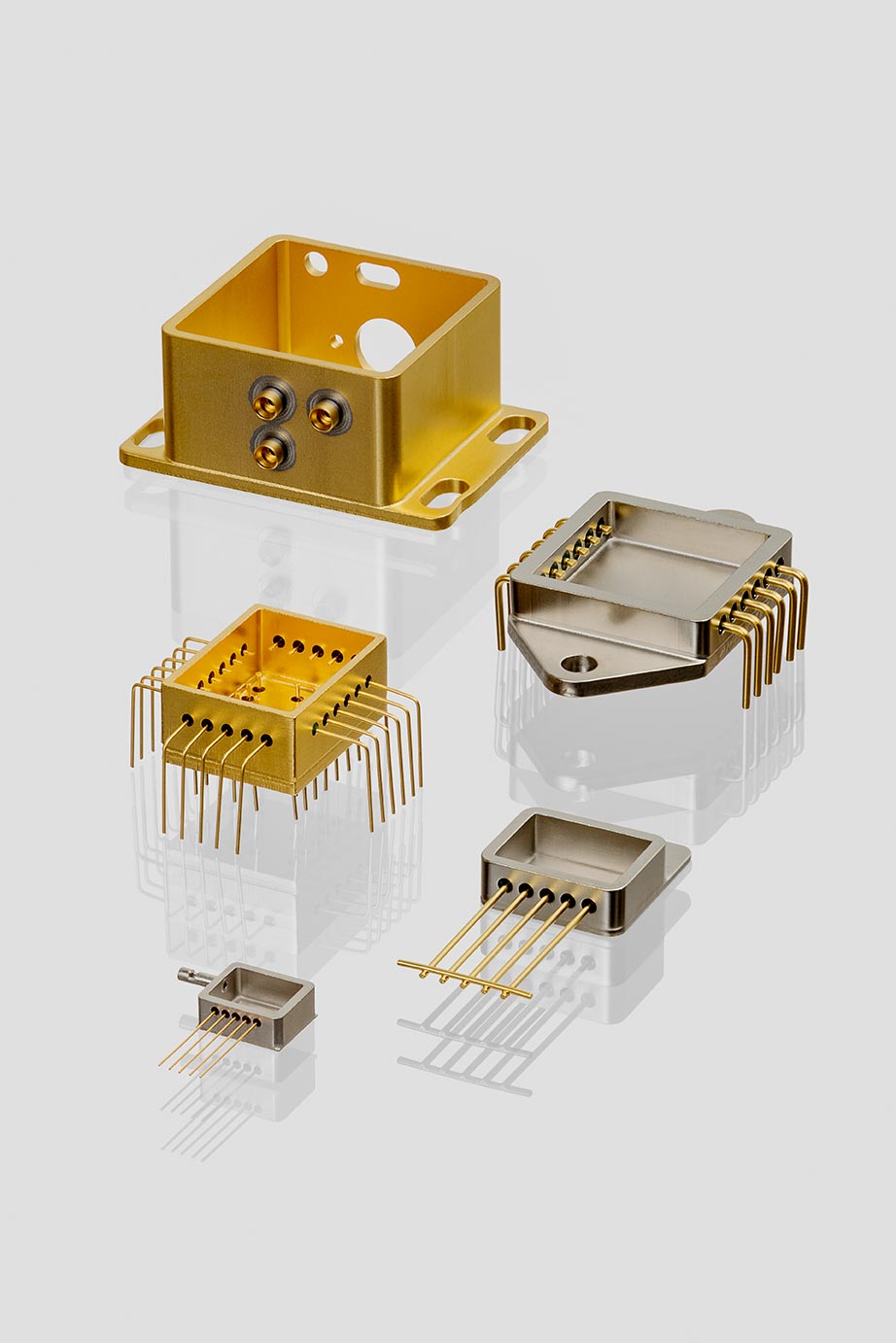

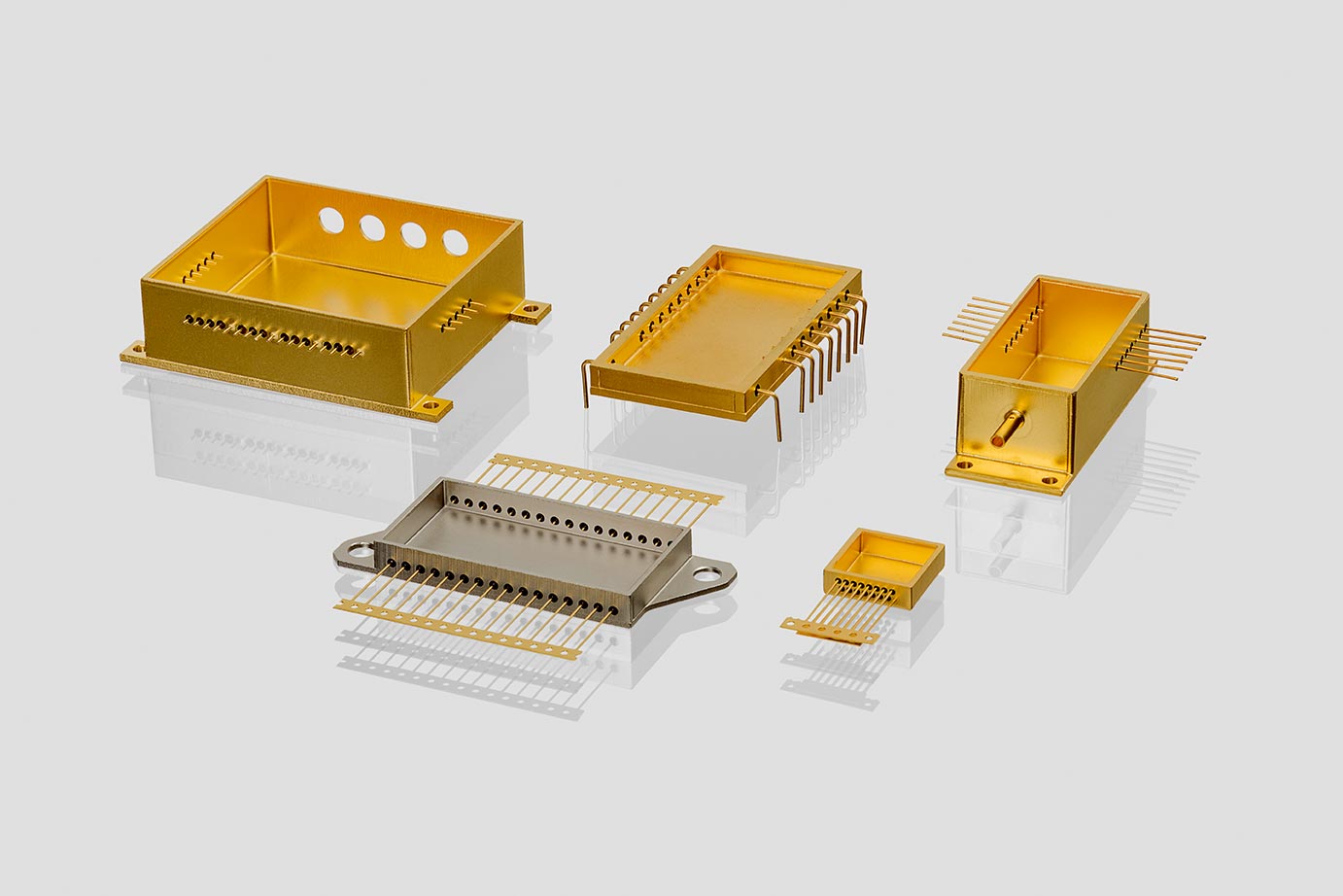

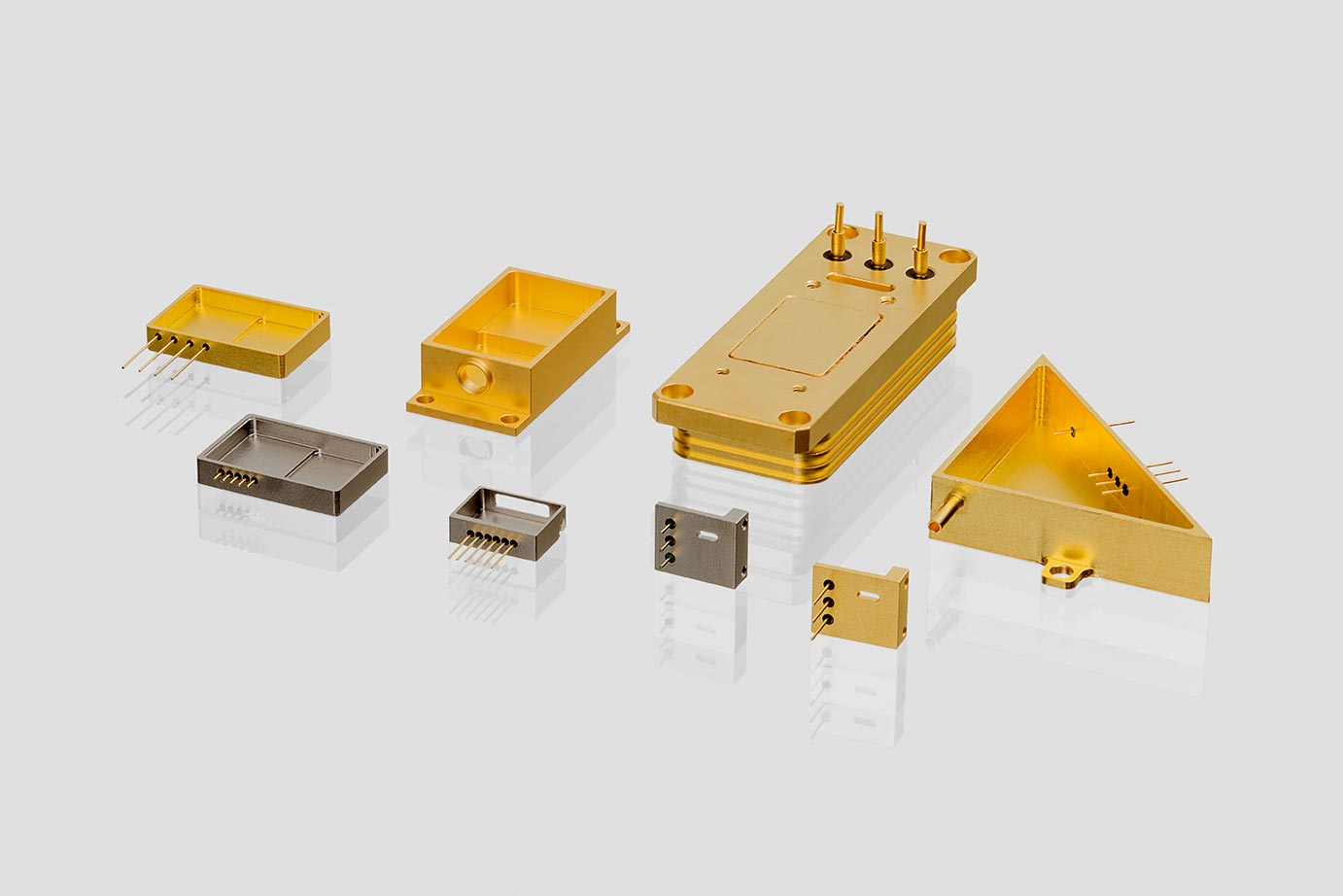

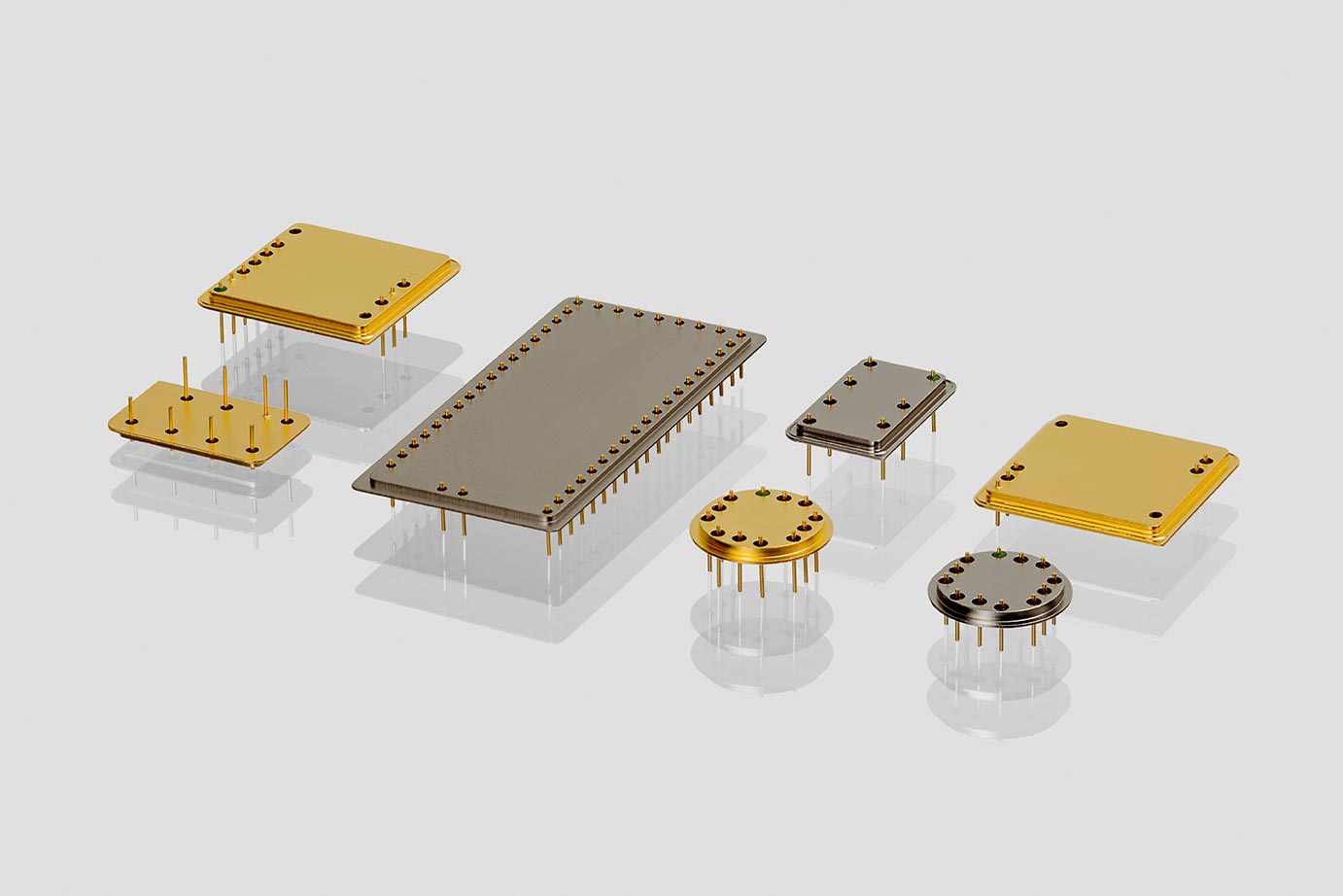

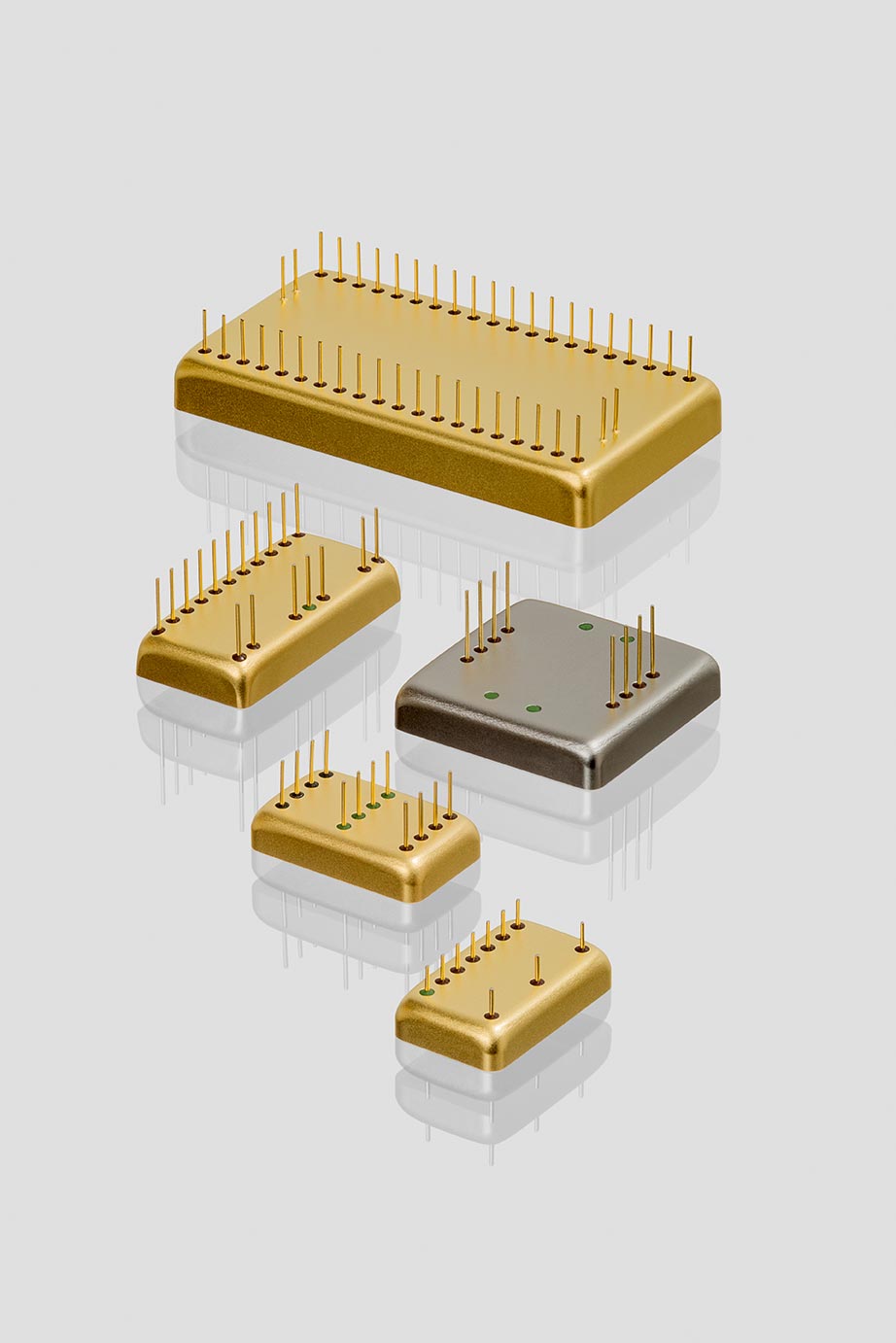

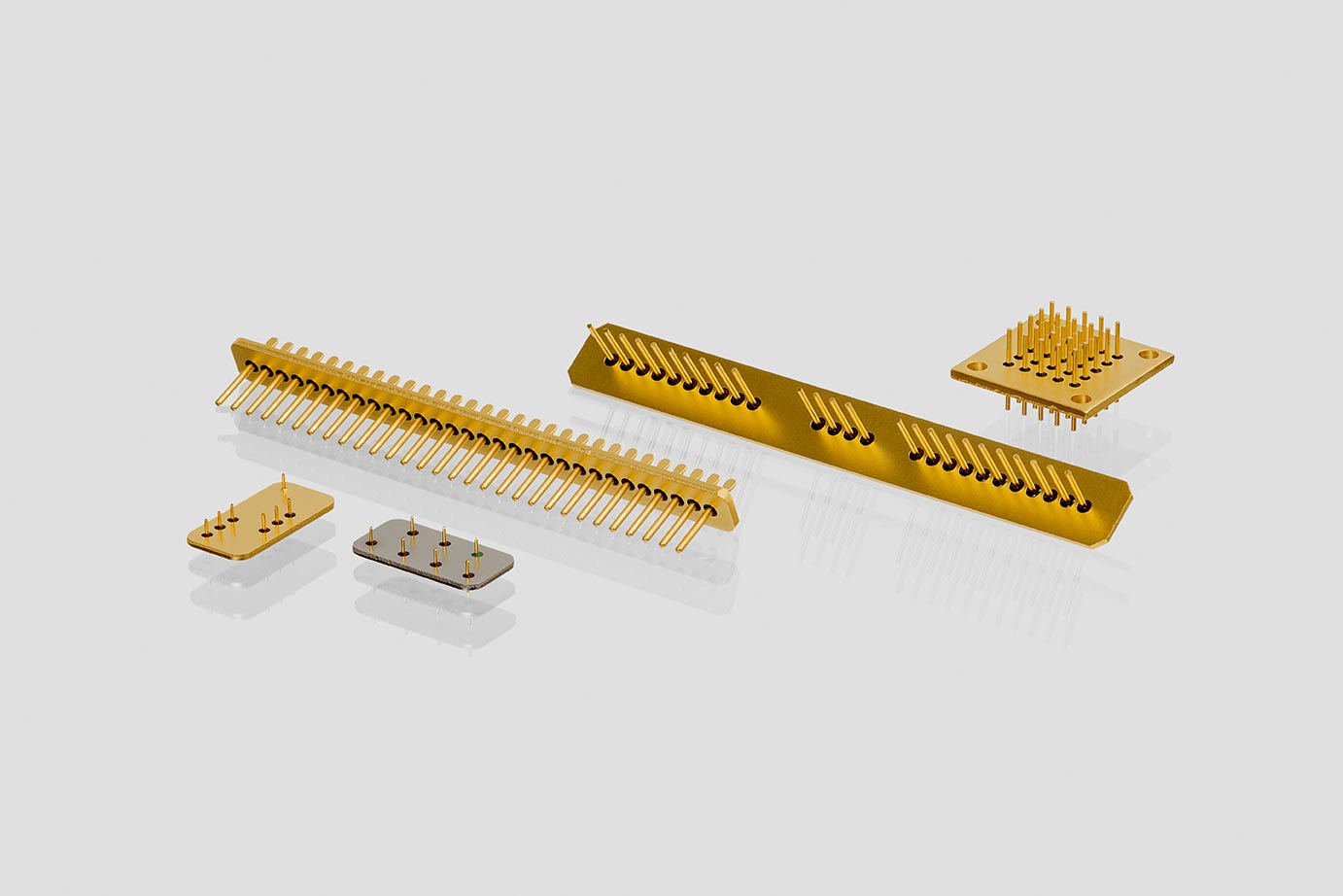

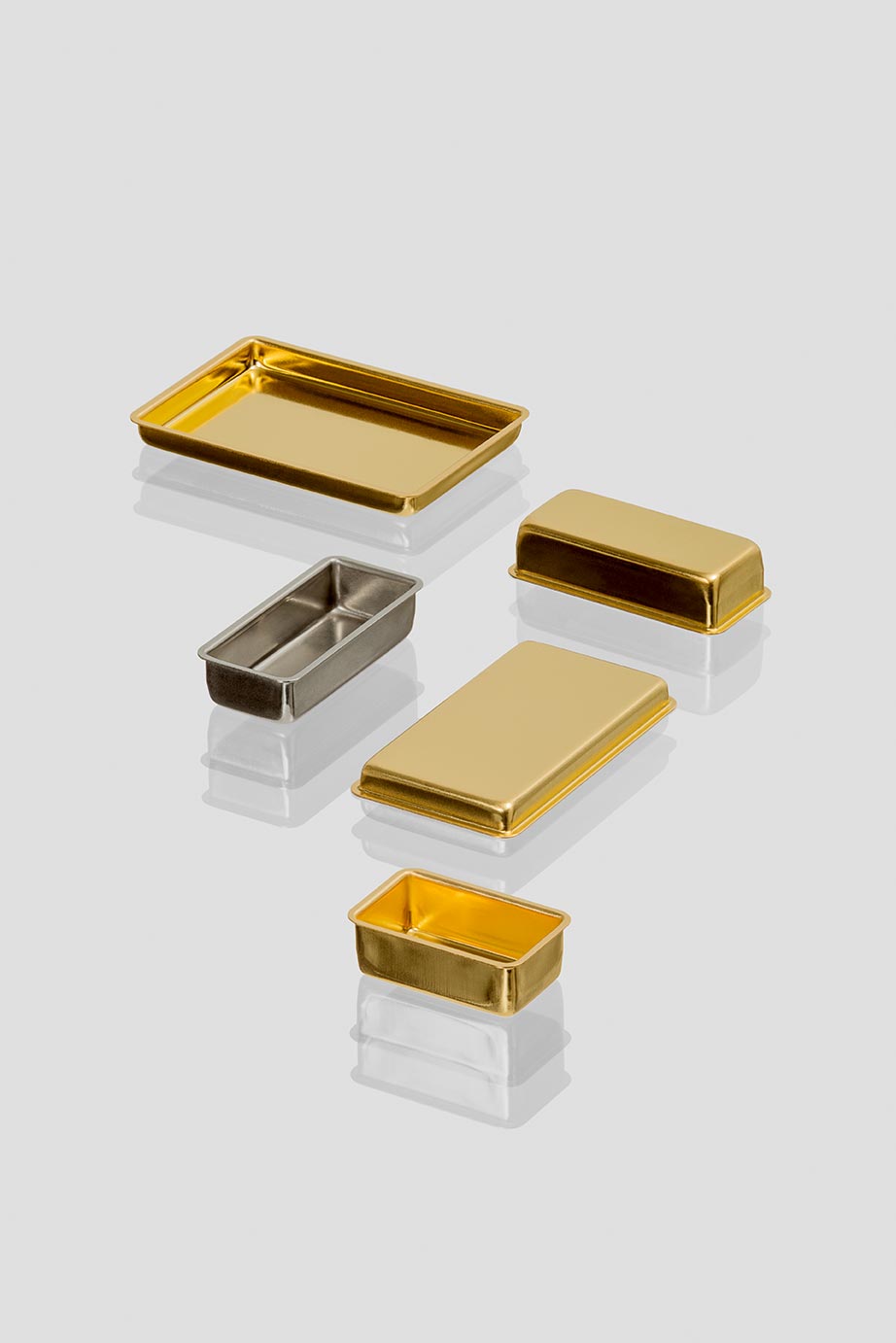

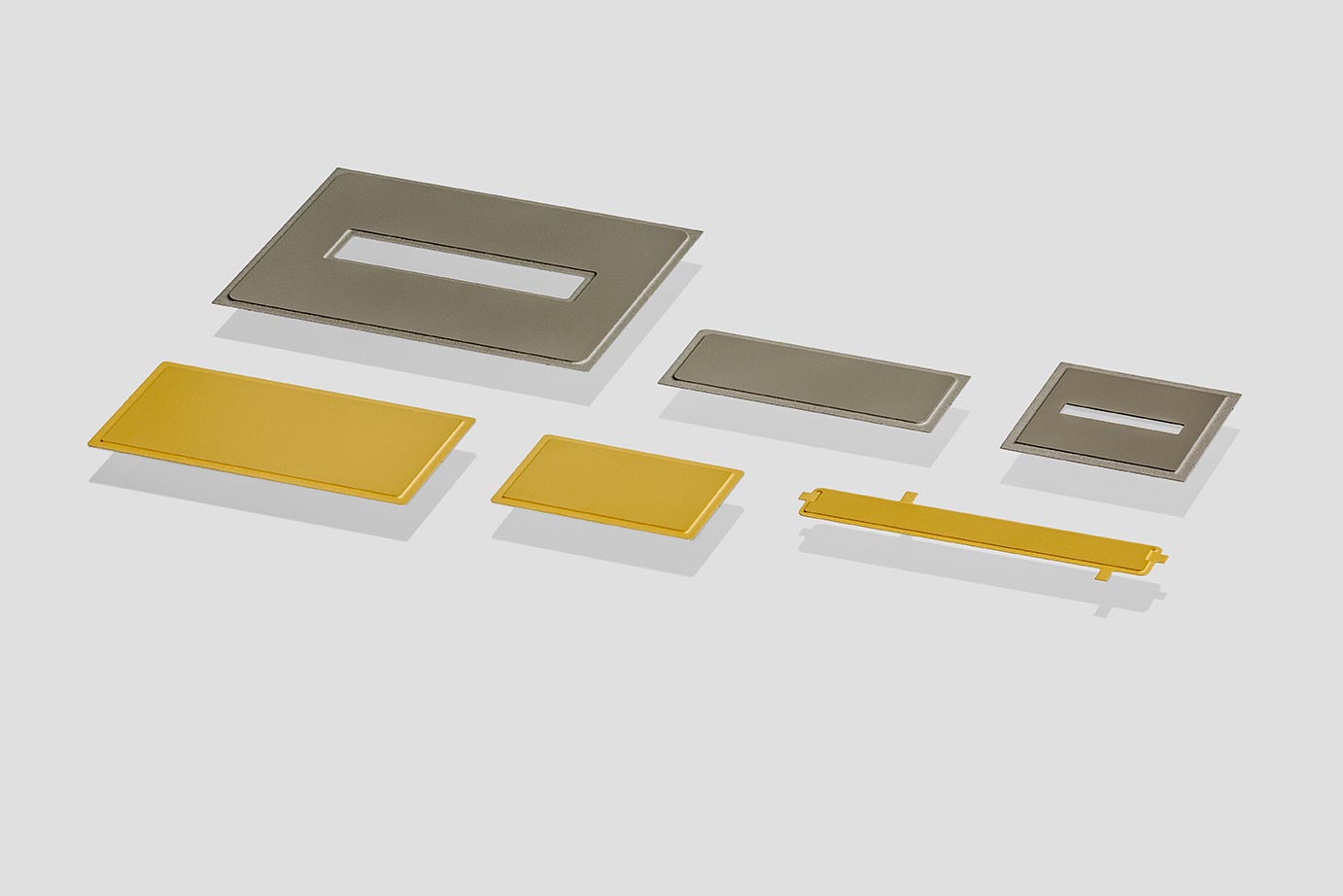

Product gallery

About our Products

Through the use of industry standard as well as unique materials, machines and methods, we manufacture hermetic housings of the highest level.

Thanks to our precise machining capabilities we can achieve tight tolerances for Kovar-, stainless steel- and other expansion alloy- housings.

We offer special and individually tailored customer specific solutions which protect the electronic equipment in your devices, independent of the extreme environmental conditions to which they are exposed. We are able to guarantee this through the Glass to Metal Hermetic Sealing which we have perfected.

The Glass to Metal Hermetic Sealing is a fusion technique in which the glass is hermetically bonded to the metal with a compression or matched seal. These housings establish the connection of internal microelectronics to the external environment by means of a hermetically glazed feedthrough.

Hermetic Glass-Metal-Seals have the following advantages

Hermeticity

High level of resistance to corrosion

High level of resilience to impact and vibration

Moisture resistance

Temperature resistance and stability during temperature cycling

Long service life

The Soldering can be combined with the Glass to Metal sealing process. This is often used to attach additional components which do not need to be electrically isolated.

Technotron offers soldering in a wide range of temperatures. For example.: AgCuPd, AuSn.

Technotron also offers various options for surface finishing, which is typically performed after the sealing process.

These serve either for corrosion protection or to optimize the surface resistance or bondability. On request, selective gold plating or masking may be applied.

The semi-finished products required for the Glass to Metal Sealing can be manufactured by Technotron from a large range of materials.

For example, ASTM F-15 (Kovar®), Alloy 42, Alloy 48, Alloy 52 Copper (Cu), Molybdenum Copper (Mo70Cu30), Steel (CRS), Stainless Steel and many more.

For further information with regard to the types of packages, materials, housing design, soldering and surface coating, please visit Downloads or contact us directly with your questions and wishes.